Siemens Flow Solution

Related Products

OBJECTIVE

The Operator of the site was required to monitor the mine discharge level and control the flow into local river network in accordance to SEPA regulations.

Processplus were contracted to design, install, and maintain the instrument solution to ensure the discharge consents were within the strict parameters set by the regulating authority.

SOLUTION

Processplus surveyed the site to assess the access requirements, compile a scope of works to provide the regulatory measurement and discharge consent.

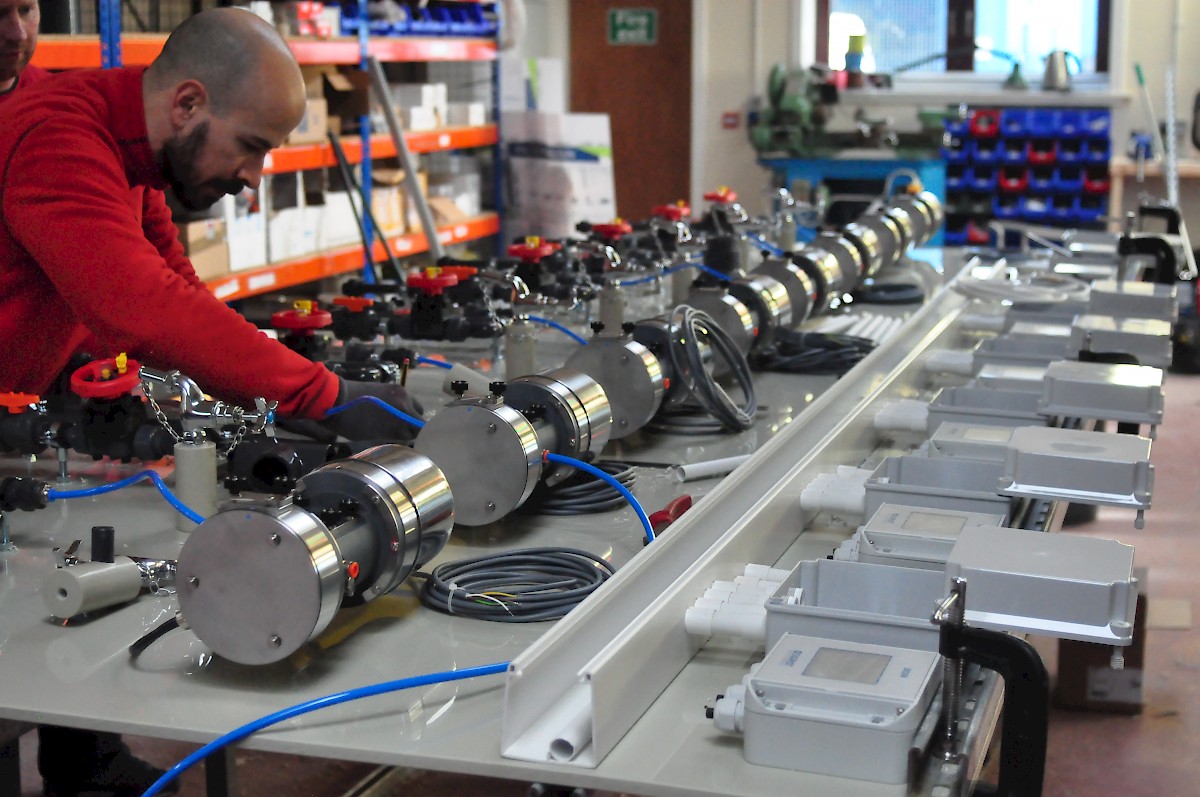

As an Approved Siemens Partner Processplus were able to supply and install Siemens flow metering on all the discharge points from the mine.

The Siemens DN300 flow meter was installed on the main mine discharge to the river and a further two Siemens DN100 flow meters were used on the mine shaft thus allowing discharge to be filtered through the reed beds before entering the river network.

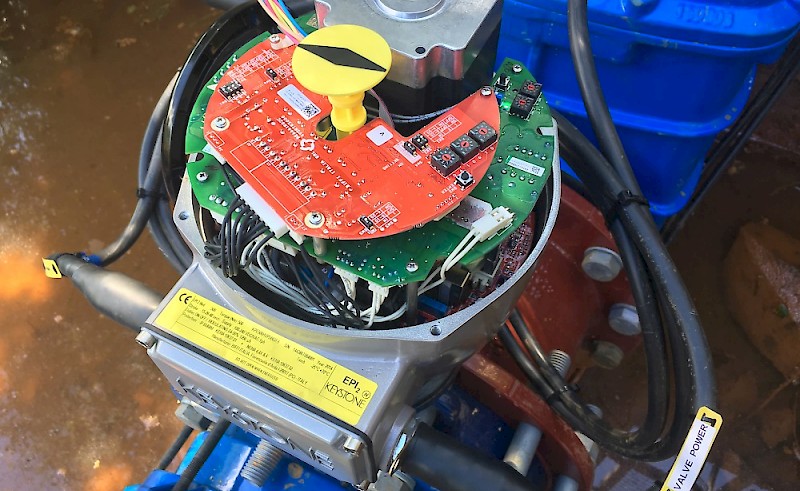

The operation of the main discharge flow was controlled by two factors, the level in the river and the function of an electrically actuated control valve. The solution had to account for the river level being at a minimum depth of 0.6m before any discharge was released. A Siemens Hydro-ranger 200 HMI, with a XRS-5 ultrasonic transducer level was mounted on the bridge above the river.

The analogue signal 4-20mA could then be transmitted via Ethernet back to the small control building at the mine site. The signal transmitted to a Siemens RD500 control system which then outputted a 4-20mA signal to the Pentair controlled valve. This provided accurate control rate of flow at predetermined set points, specified by SEPA requirements depending on the river level.

The GRD data logger takes the analogue and pulse outputs from all the instruments which results in a web based monitoring system functioning through an IP address. This provided full visibility to the coal authority and the facilities management company who were responsible for the site.

The overall project provided a cost effective and accurate solution using market leading technology and common interfaces to ensure the ease of usability for the local site operators.