Instrument Verification

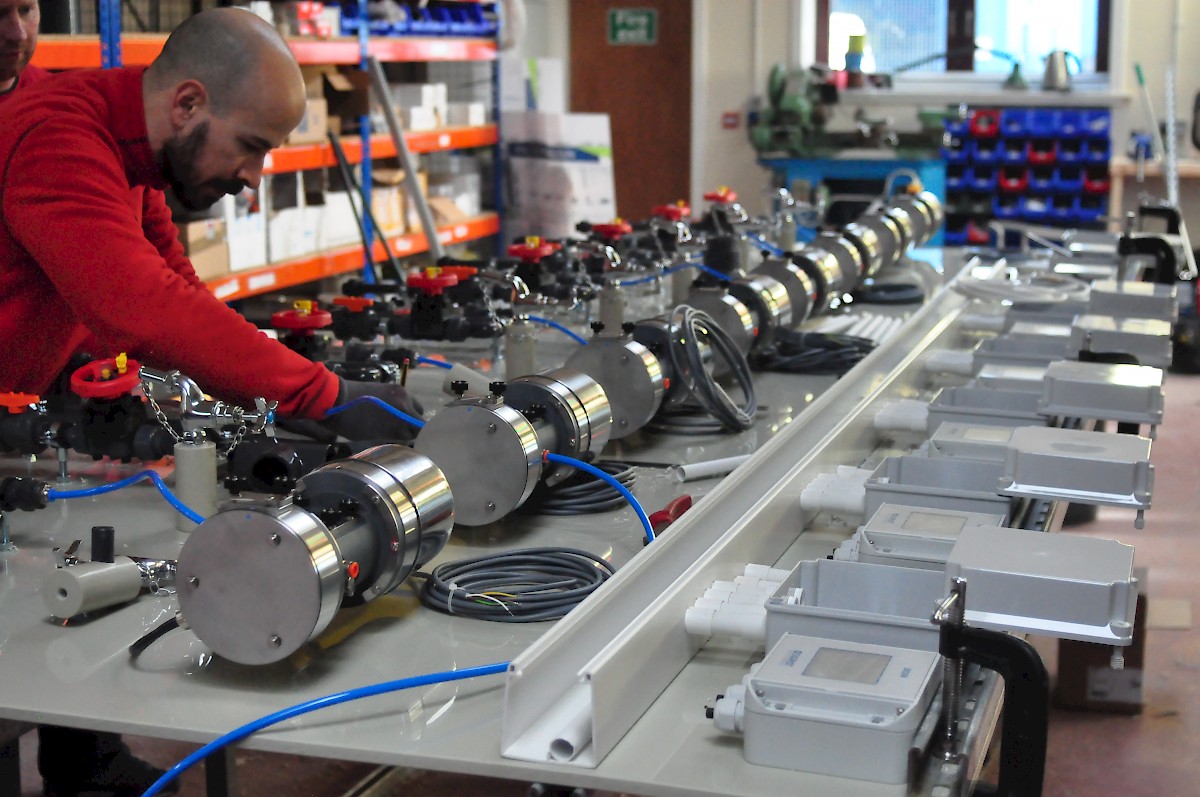

The Importance of Regular VisitsA regular maintenance site visit to a multi-national dairy producer included verification of their pH and temperature instruments.

A change of sensor from ORP to pH. The sensor was removed from the process and cleaned. The test was carried out using buffer solution and at each test point, the sensor was given time to stabilise before taking a reading. The readings were then recorded and reported to the Operations Manager.

A temperature test indicated an error which equated to approx. 0.01pH.

At the time the Processplus engineer noted that heavy corrosion and damaged pins were found in the connector between the sensor and extension cable. This was resulting from the flooding of the enclosure (see attached image of water mark). Although this sensor was still functional, it was recommended this these parts are changed before corrosion progresses to the point of a fatal error disrupting the process.

A full report with recommendations was submitted and discussed with the Operations Manager with a number of key areas identified for further work.

The importance of regular site visits and process instrument maintainance ensures the operation does not have to enforce a costly shut down.

Processplus provide maintenance contracts tailored for client sites to ensure instruments continue to perform accurate and reliable measurements.

Contact our Technical Team for further information.