Real Time Measurement & Control of Process

In the oil and gas industry, instrumentation is used to monitor and control the operating conditions of the facility. It follows that this ensures safety, environmental regulations, as well as quality and productivity, whilst maintaining a profitable and stable plant.

The two main areas include -

- Input Instrumentation - measuring & monitoring the different process variables

- Output Instrumentation - measuring & monitoring the parameters to the final control system

The input instrumentation measures four operating parameters: pressure, temperature, flow and level. Advanced, online analysers that measure process composition are also considered an element of process instrumentation.

The instrumentation consists of three main components:

- A sensor

- A transducer

- A transmitter

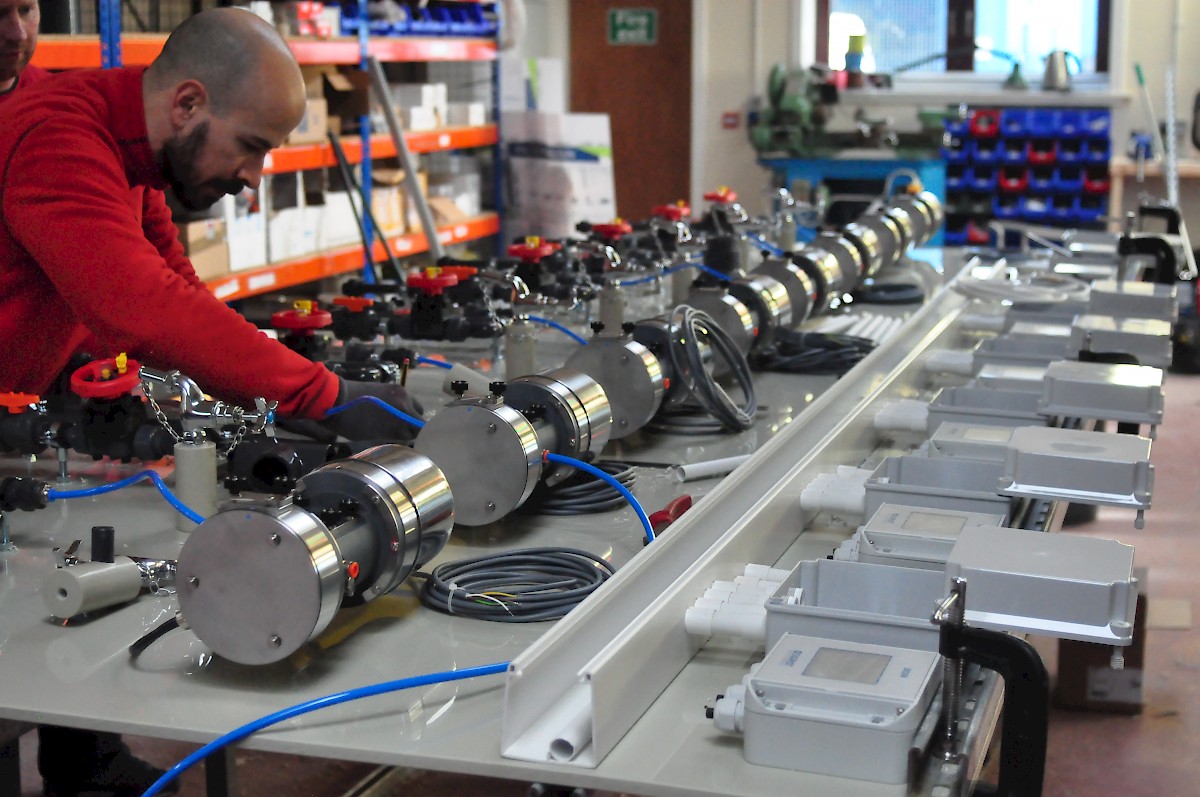

Process instrumentation includes the most common control element, the control valve, which consists of an actuator that converts the output signal from the control system into a signal that can allow the valve to respond, the positioner for adapting the response and the valve. Smart positioners can send and receive useful data to and from the control system for predictive maintenance purposes.

With our team of qualified offshore engineers Processplus are able to assist with the specification in design stage as well as the install and mainenance of process instruments in the oil and gas industry.