Suspended Solids Solution

Manufacturing IndustryRelated Products

Client

The largest UK manufacturer of leather in the UK.

Background

Wastewater from the manufacturing process must be treated to meet legislative compliance before the water can be discharged from the site.

A Dissolved Air Floatation (DAF) process is used as part of the treatment process and to evaulate the performance of the DAF plant a suspended solid probe was installed in the DAF discharge pipeline.

The suspended solids probe, a Hach Solitax probe, was not measuring correctly and giving very erratic readings.

Objective

An initial site survey was carried out whereby Processplus engineers were able to view and assess the Hach Solitax Probe installed within the pipeline.

The process was reviewed and Processplus were asked to provide a solution that would ensure the Solitax was in the right part of the process to provide a reliable and accurate independent measurement.

Challenge

The current location of the Hach Solitax Probe was proving restrictive, giving inaccurate readings and on many occasions, it gave no readings at all. A number of reasons were identified as the cause, these included a high flow discharge velocity within the pipe, a build up of fatty deposits from the process which would foul the probe and the lack of accessibility to check and clean the probe due to its location in the pipeline. The prove was 2 to 3m above ground level with no easy access available for an engineer to inspect the probe.

Solution

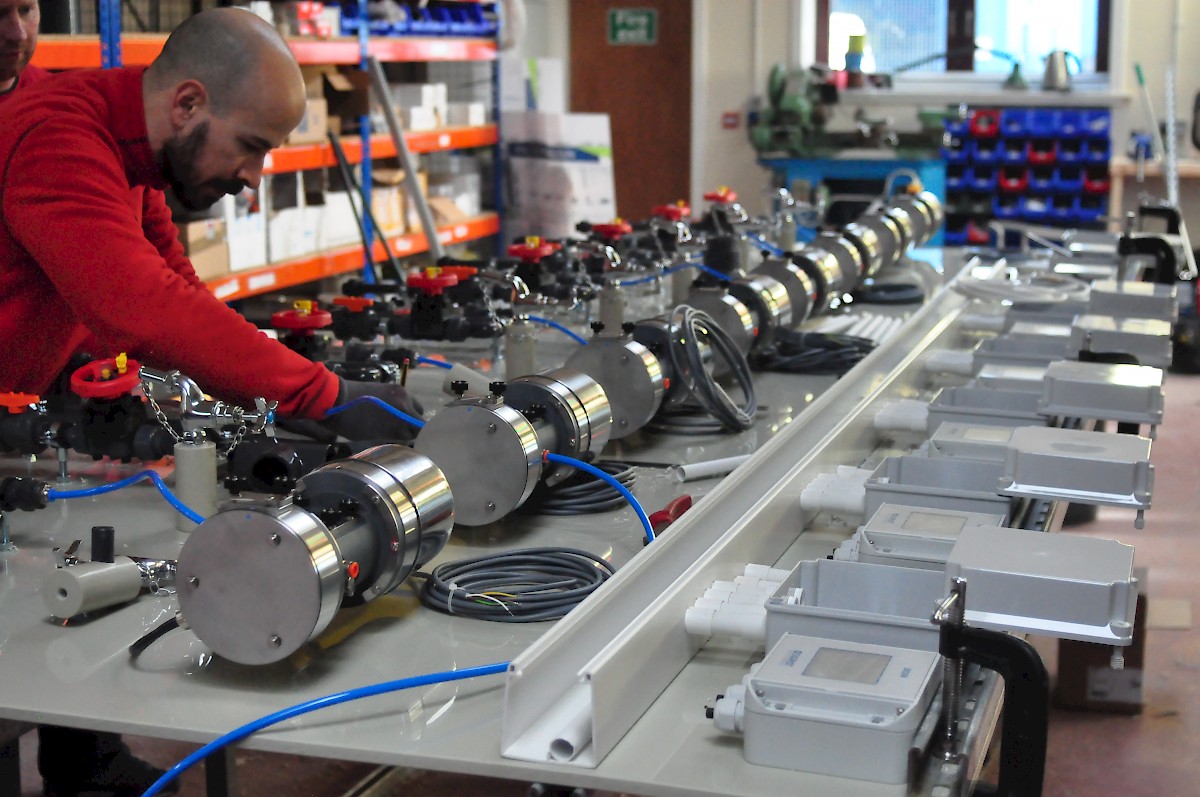

The engineering team identified that by designing a stainless steel, flow conditioning bypass tank, it would allow the flow velocity to be reduced, remove the potential of any air bubbles and allow fatty solids to be settled out and not come into contact with the probe. The tank would be designed to suit the clients site process to ensure the probe could be easily accessed for regular checks, cleaning servicing and future maintenance.

The full solution included the manufacture, supply and installation of the new flow conditioning rank and associated pipework, the removal, relocation and reinstallation of teh existing probe into the flow conditioning tank.

Result

The site installation of the new flow conditioning tank was carried out by Processplus service technicians. The system was fully tested and commissioned.

The Hach Solitax probe measurement was stable, accurate and the client can now confidently rely on the suspended solids measurement from the DAF discharge to accurately understand how the DAF plant is performing.