Tank Level Solutions, Alness

A remote location with a project completed ahead of time and on budgetRelated Products

Sureclean is a Scottish based company with headquarters in Alness. A well-established international services contractor, providing specialist solutions to the Oil & Gas, Petrochemical, Renewable, Utilities, Civil Engineering and Construction sectors.

The tank storage and subsequent processing of liquid waste is an important area of Sureclean’s business. In order to optimise the use of tanks at their Alness site and avoid exposing their personnel to risks associated with manual inspection of tank levels Sureclean opted for a tank level monitoring system. Processplus were able to assess the requirement and identified that the most cost effective solution would be delivered via Siemens ultrasonic continuous level monitoring equipment.

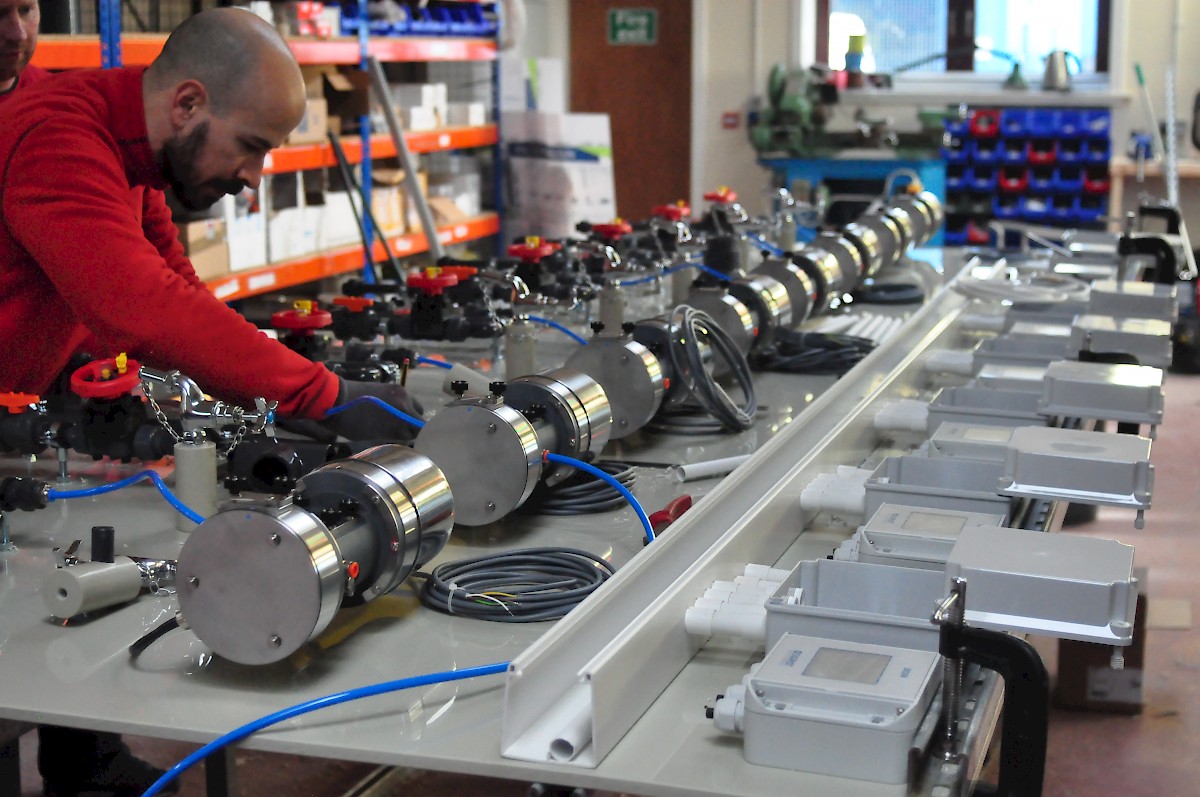

The non-contact solution consists of a XRS5 transducer (suitable for tanks up to 8 m high) mounted on each tank with each transducer connected back to a level monitor that is conveniently located at ground level.

The 12 tanks at Alness were dealt with by a single LU10 and a MultiRanger unit for the remaining two tanks situated some distance from the others.

After more than 24years in use the monitoring of the 29 tanks has proved to be both reliable and accurate and virtually maintenance free. This has led to better utilisation of storage capacity and eliminated the need for personnel to inspect tank levels thus reducing the risk of falls and slips particularly in severe winter weather.

Processplus have wide experience of the implementation of point and continuous level solutions using both contact and non-contact techniques. Technologies used range from simple float switches, through capacitance and ultrasonic to radar and laser. With hundreds of installations throughout Scotland, Processplus can provide, install and commission a level monitoring system to suit your company’s needs.