Invercannie, Aberdeenshire

With performance critical analysis of Dissolved Organic Carbon required at Invercannie WTW, Scottish Water Operations engaged Processplus to design, install, commission, and test, real time water quality measurement systems within the Membrane Plant.Related Products

As part of their Capital Maintenance Program, Scottish Water undertook a membrane replacement project at Invercannie WTW, located on the side of the River Dee in Aberdeenshire. A critical element of this project was to monitor the performance of the membrane stacks with respect to the removal of the Dissolved Organic Carbons inherent in the raw process water being abstracted from the River Dee.

Following an initial site survey of the Membrane Plant, Processplus Engineers concluded that a bank of eight Sigrist ColorPlus DOC analysers would be their preferred solution. These analysers would be installed at a location to allow both ease of access and ease of maintenance for the plant operations team.

New sample supply pipe work would be required to connect each of the eight membrane stacks to the new Sigrist DOC analysers. Conscious of operational constraints Processplus Engineers designed a pipe installation that utilised available height within the membrane building and that minimised the construction time on site.

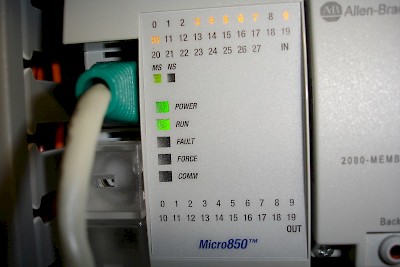

In addition it was essential that the analogue and digital signals from each analyser were connected to the membrane plant PLC. Processplus Engineers concluded that the most efficient methodology to ensure seamless integration of the new Sigrist DOC analysers would be to install a dedicated Local Control Panel (LCP) for the analysers with a dedicated Allen Bradley PLC. This PLC would then be added to the existing plant network via an Ethernet connection.

Following integration into the PLC network the plant’s SCADA system was updated and new pages were created to a format requested by the Operation Team. On completion of the SCADA upgrade the site’s Telemetry system was reprogrammed and then sensor to screen tested to Scottish Water’s Intelligent Control Centre (ICC).

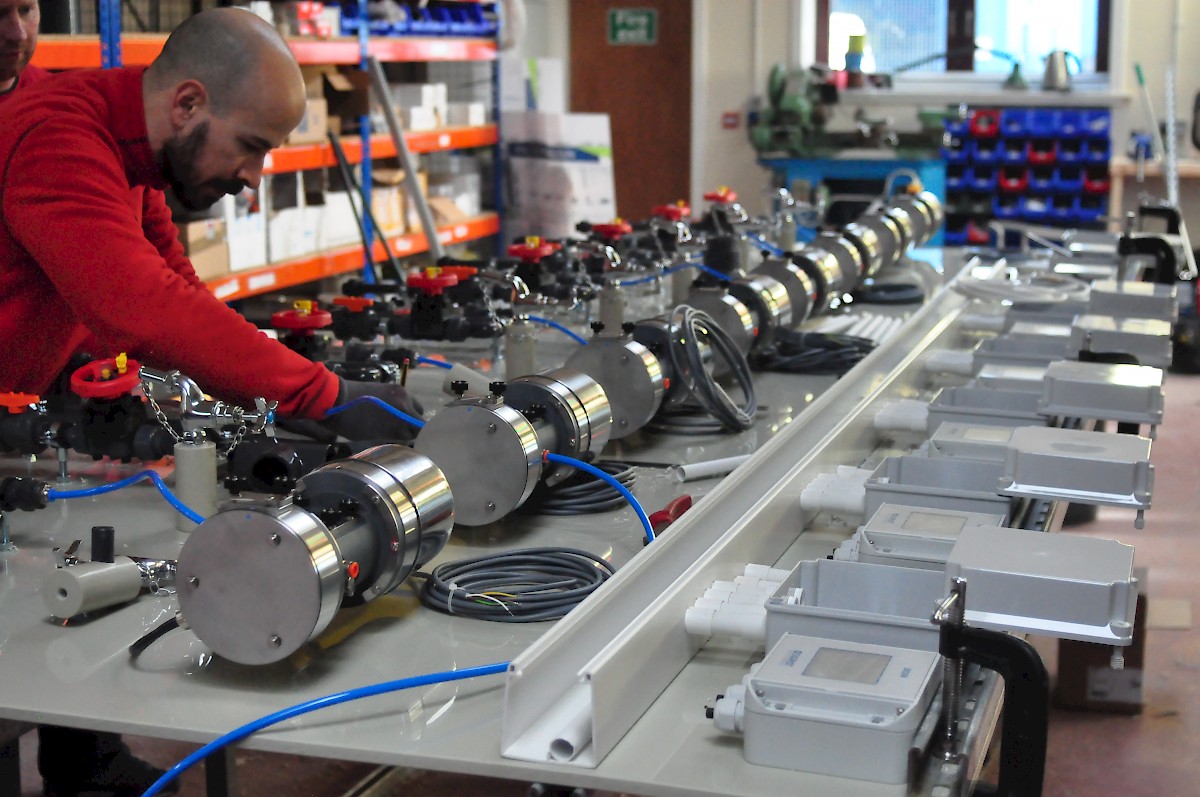

The instrument and LCP assemblies were manufactured off site at the Processplus workshops in Dunfermline and then shipped to site for installation. Pre-assembly of the instrument back boards was essential to minimise the on-site construction time and to minimise the disruption to normal plant operations.

In addition to the Sigrist DOC analyser assembly; Processplus designed, installed, commissioned, and tested a replacement Combined Water quality analysis instrument assembly. This assembly measures the Turbidity, pH, and Particle Count of the Combined Inlet Water and the Combined Outlet Water from the membrane plant. Self-calibrating Sigrist Aquascat WTM(A) turbidity analysers were selected for this application.